News & Insights

Flash Metals USA and Ucore Forge Binding Collaboration to Unlock U.S. Rare Earth Element (REE) Supply Chain Independence

September 15, 2025

Flash Metals USA, a subsidiary of Metallium Limited (“Metallium”) (ASX: MTM; OTCQX: MTMCF), today announced it has entered into a binding Technology Collaboration Agreement with Ucore Rare Metals Inc. (“Ucore”) (TSXV: UCU), a leading North American rare earth element separation company backed by the U.S. Department of War (DoW).

KEY HIGHLIGHTS:

Binding 12-month agreement: Each party will process the other’s feedstocks, integrating Flash Metals USA’s FJH with Ucore’s RapidSX™ to create the first U.S. pathway for taking a diverse range of REE feedstocks all the way to separated oxide products - a capability that, until now, has been largely confined to China.

Economics to follow test work: Results will underpin commercial discussions, incl. licensing, tolling, or JV models.

Minimal cost: Each party uses its own existing facilities; incremental costs are immaterial

Natural flowsheet fit: Flash Metals USA’s FJH rapidly upgrades complex feedstocks into clean chloride intermediates, cutting out many of the conventional processing steps, incl. acid roasting and leaching. These intermediates are directly compatible with Ucore’s RapidSX™, potentially reducing refining complexity and costs, and widening acceptable REE feedstocks, including third-party materials that would otherwise go to Chinese refiners.

Grant & funding upside: Both parties will also explore joint submissions for U.S. government grants and strategic funding opportunities to support scale-up & commercial deployment, including for the treatment of mine tailings.

Magnet recycling entry: Agreement provides Flash Metals USA with entry into the U.S. magnet recycling market, a rapidly growing downstream sector, through a magnet-scrap-to-separated REE pathway.

Heavy REE focus on dysprosium (Dy) and terbium (Tb), among the most supply-constrained & strategic REEs.

Strategic upside: Success could enable Ucore to process a broader range of feedstocks, including mine tailings, and position Flash Metals USA as a supplier of upgraded intermediates, while also unlocking new pathways for REE developers currently reliant on non-U.S. refiners.

Texas demonstration plant: Flash Metals USA’s 1-tonne-per-day e-waste commercial demonstration facility remains the Company’s core focus and is on track for commissioning by December this year.

Parallel initiatives: Flash Metals USA continues collaborations with Meteoric Resources (ASX: MEI) on Brazilian MREC and with Rice University on a parallel direct REE separation route using FJH.

Aligned with growing U.S. Federal Government backing for domestic REE supply chain independence, including the DoW’s US$400m equity and 10-year NdPr floor price deal with MP Materials and a growing number of grants.

The Agreement commits each party to process feedstocks supplied by the other at its existing facilities, Flash Metals USA’s FJH platform in Houston and Ucore’s RapidSX™ facility in Louisiana, with results shared to inform downstream economics. Costs will be borne individually and are immaterial. Flash Metals USA’s FJH provides the upstream upgrading step, converting diverse feedstocks into high-purity chlorides in a single rapid process, significantly reducing the complexity of conventional REE metallurgy. Ucore’s RapidSX™ delivers downstream separation into individual rare earth oxides. Together, they create a potential end-to-end U.S. refining pathway for REEs, with commercial terms to be determined following test work.

Flash Metals USA, a Metallium Company, Managing Director & CEO, Michael Walshe, commented: “Ucore is constructing the most advanced REE separation facility in North America, and this Agreement positions Flash Metals USA at the front end of that supply chain. Our FJH platform can unlock feedstocks that are currently stranded or heavily discounted, particularly those rich in heavy REEs. FJH also removes much of the traditional separation burden upfront, simplifying the flowsheet before RapidSX™ takes over. By combining technologies, we are jointly building the foundations of a sovereign, U.S.-based refining pathway.”

“In parallel, we continue to progress our Meteoric and Rice University collaborations, and our Texas demonstration plant remains firmly on track for processing e-waste next year.” Ucore Chairman & CEO, Pat Ryan, commented: “We are excited to explore the integration of Flash Metals USA’s metal recovery platform with our RapidSX™. This collaboration directly supports the U.S. Government’s strategic objective of developing Western-aligned separation capabilities that are scalable, flexible, and feedstock-agnostic. Our goal is to deliver consistent, high-purity rare earth outputs suitable for critical defense and commercial applications. The combination of Flash Metals USA’s chloride-based upgrading and our DoW-backed RapidSX™ platform positions both companies at the center of a resilient U.S. supply chain”.

Figure 1: Ucore Chief Operating Officer Michael Schrider & Flash Metals USA (FMU) President Steve Ragiel at FMU’s lab in Texas

Figure 2: Flash Metals USA (FMU) non-executive director Tony Hadley & FMU President Steve Ragiel inside Ucore’s SMC facility in Louisiana.

THE OPPORTUNITY

Rare earths are not rare, but refining them into usable form is one of the most complex supply chain challenges in the world. China currently controls ~85% of global refining and >95% of heavy REE separation. This has left the majority of Western mines and recycling streams stranded with no path to final refined products without sending material to China.

Rare earth metallurgy is especially complex. The elements occur together in nature with uranium, thorium and other impurities, and because their chemical properties are so similar, they are extremely difficult to separate. Conventional refining typically requires thousands of solvent extraction stages, generating radioactive tailings and high costs. The commercial focus is on the “magnet” REEs, neodymium, praseodymium, dysprosium and terbium, which must be separated to 99.99% purity for end-use in EV motors, wind turbines and defense systems.

Flash Metals USA’s FJH is designed to address these challenges by upgrading complex mixtures into chloride intermediates in a single step, avoiding the thousands of solvent extraction stages normally required and providing a clean input stream for Ucore’s RapidSX™ separation.

The Flash Metals USA–Ucore partnership seeks to address this bottleneck:

Feedstock-agnostic: mine concentrates, mixed rare earth carbonate (MREC), tailings, magnet scrap, and e-waste.

Sovereign pathway: enables U.S.-based refining without reliance on Chinese infrastructure.

Heavy REE focus: delivers, amongst others, terbium & dysprosium, critical for EV motors and defense systems.

FJH produces chloride intermediates that plug directly into Ucore’s RapidSX™ platform, a natural fit that could shorten refining steps, improve economics, and provide Ucore with greater feedstock flexibility, while creating new pathways for third-party REE developers to access U.S. refining capacity.

RapidSX™ OVERVIEW

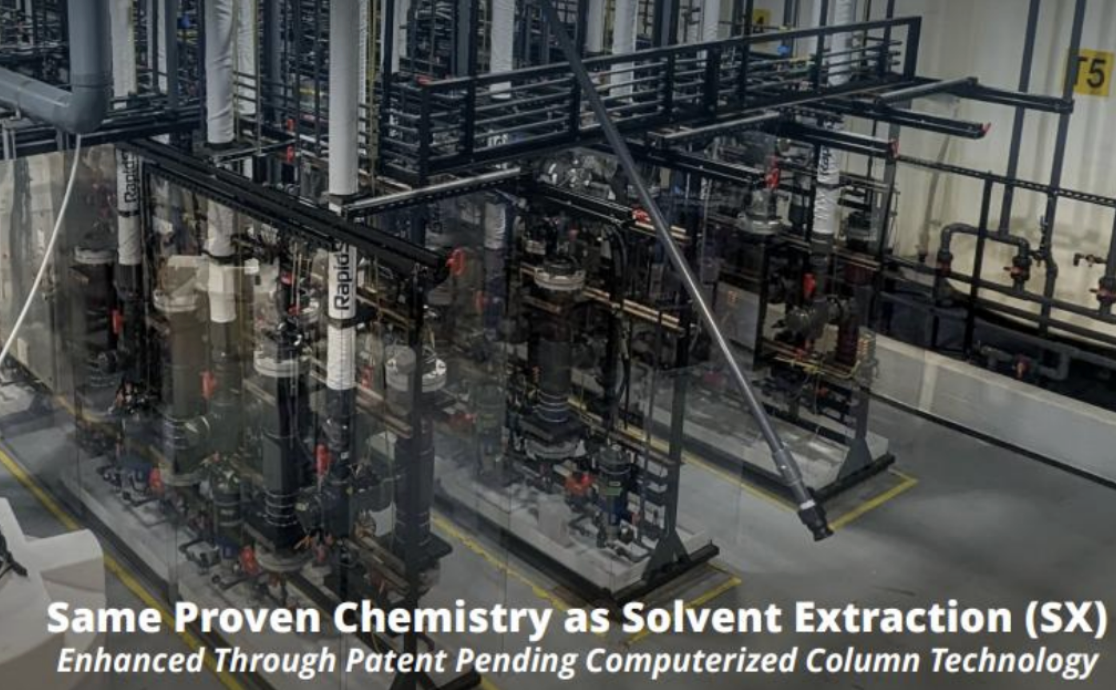

RapidSX™ is Ucore’s proprietary rare earth separation technology, designed as a next-generation alternative to traditional solvent extraction (SX), which is the industry-standard technology employed for REE separation currently. Unlike conventional SX circuits, which can require several hundred mixer-settler stages, RapidSX™ delivers the same chemical separation principles through a shortened, more efficient column-based system and has been demonstrated to separate mixed REE feedstocks up to three times faster than a similar conventional SX plant. This reduces the number of processing steps, lowers capital and operating costs, and improves environmental performance.

The technology is chloride-compatible, making it a natural fit with Flash Metals USA’s FJH-upgraded feedstocks, and is being scaled at Ucore’s SMC facility in Louisiana with direct funding support from the U.S. Department of War.

Figure 3:RapidSX™ 80 tpa Commercialization and Demonstration Facility (CDF) Kingston, Ontario

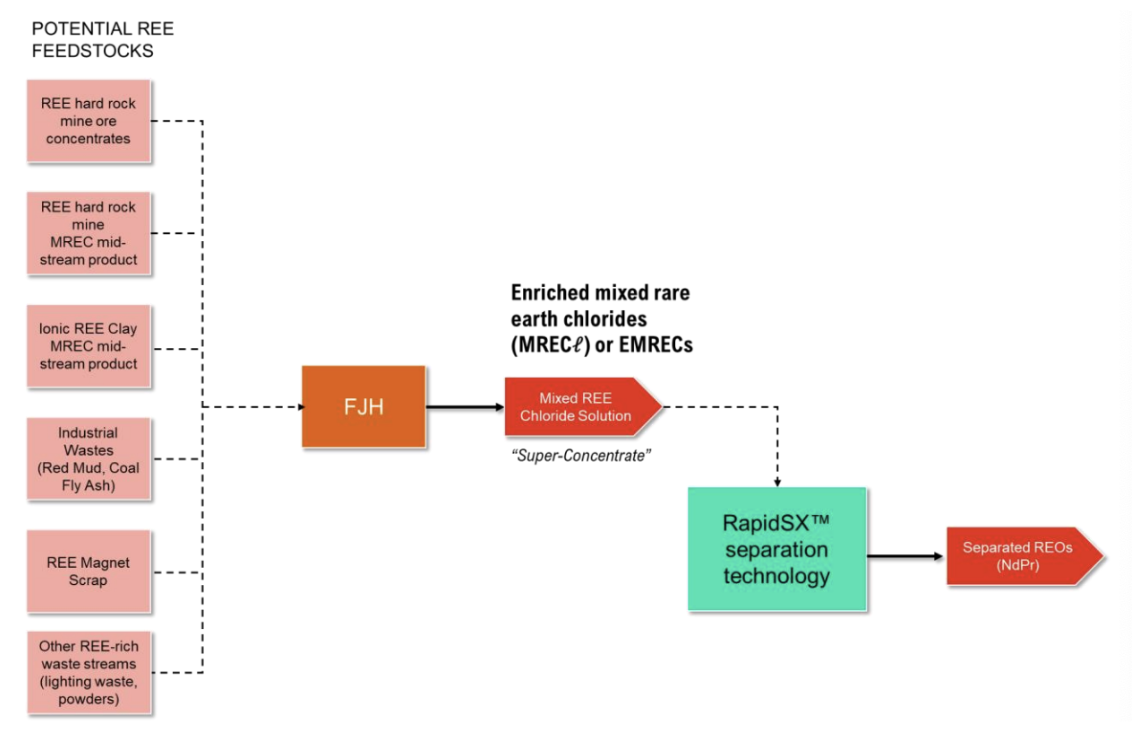

Flash Metals USA’s FJH technology acts as an upstream upgrading step, producing chloride intermediates that are then refined into individual REEs using Ucore’s RapidSX™ separation platform. The diagram below presents a modular rare earth element (REE) refining pathway capable of processing a wide range of REE-bearing feedstocks. These include primary mineral concentrates, mid-stream MREC from ionic clays, recycled materials (e.g. rare earth magnet scrap), and industrial residues (e.g. red mud, coal fly ash).

Figure 4: Integrated FJH–RapidSX™ Flowsheet for Multi-Feedstock Rare Earth Refining

Using Flash Metals USA’s proprietary FJH process, these inputs are upgraded into high-purity mixed REE chloride intermediates. The resulting solution is then conditioned and processed via Ucore’s RapidSX™ separation platform to produce individual rare earth oxides (REOs), such as neodymium-praseodymium (NdPr). This integrated flowsheet represents a scalable, nonChinese alternative to traditional sulphate-leach and solvent extraction processes, suitable for both conventional and unconventional REE sources.

COLLABORATION SCOPE

Under the binding agreement, Flash Metals USA and Ucore will:

Collaborate on integrating Flash Metals USA’s FJH-based chloride upgrading technology with Ucore’s RapidSX™ separation platform across a wide range of feedstocks. The collaboration will explore opportunities to bypass conventional acid-leach circuits by converting REE-bearing feedstocks into enriched mixed rare earth chlorides (MRECℓ) or ‘EMRECs’, selectively remove deleterious elements, and apply FJH as a pre-treatment for high-Fe/Al feedstocks to enable their acceptance in downstream systems.

The parties will also investigate the recovery of the highly strategic heavy REE terbium (Tb) and other high-value elements from lighting waste and phosphor powders.

In parallel, Flash Metals USA is continuing research with Rice University on the potential application of FJH for REE separation, ensuring the Company maintains multiple technical pathways while aligning with Ucore on near-term commercial deployment.

NEXT STEPS

The 12-month collaboration will advance through a staged program of testwork and pilot operations. In the first stage, bench-scale testing will focus on processing Ucore’s rare earth concentrate through Flash Metals USA’s FJH system to produce mixed REE chlorides, the conversion of magnet scrap into chlorides containing neodymium, praseodymium, dysprosium and terbium, and the extraction of terbium from lighting waste.

In the second stage, pilot-scale production will involve pilot campaigns to produce mixed REE chlorides (MRECℓ) for feed into Ucore’s Kingston separation facility.

The testwork program is expected to take approximately six to nine months, although actual duration may vary depending on feedstock campaigns and technical results.

This second stage will also test the viability of applying Ucore’s RapidSX™ to mixed metal chlorides derived from e-waste processed using FJH.

This staged program combines Flash Metals USA’s front-end upgrading capability with Ucore’s downstream separation capacity, reflecting the complementary roles of each technology within the integrated flowsheet.

The results of this staged program will underpin evaluation of commercial models, including licensing, tolling, and joint ventures.

In parallel with this collaboration, Flash Metals USA is also continuing its research program with Rice University, focused on the application of FJH technology directly to REE separation. This work is complementary to the Ucore partnership and underscores Flash Metals USA’s strategy of advancing multiple technical pathways for critical metal recovery.

Furthermore, Flash Metals USA is also advancing its existing collaboration with Meteoric Resources (ASX: MEI) under a signed MOU to apply FJH to MREC feedstock from Meteoric’s Caldeira project in Brazil. That testwork has already demonstrated a step-change uplift in magnet and heavy REEs, providing further validation of Flash Metals USA’s chloride-based upgrading pathway.

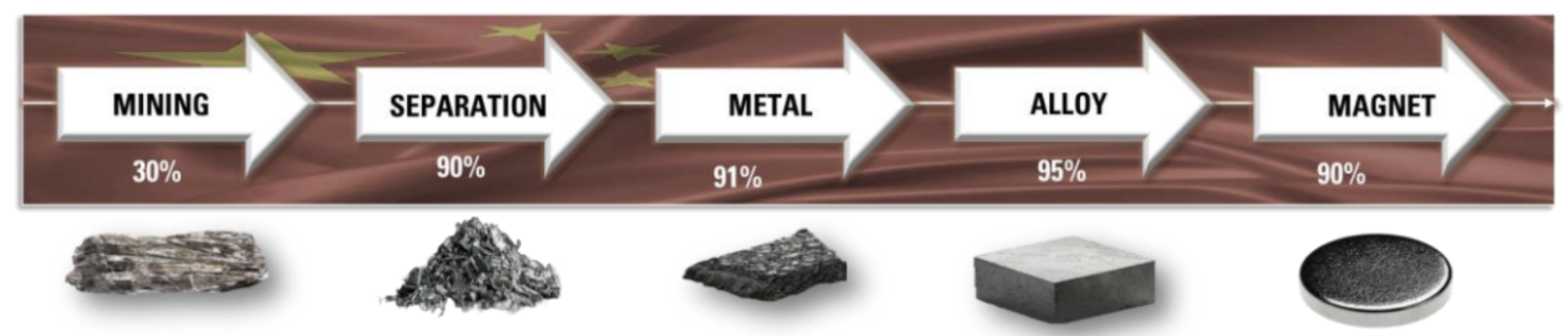

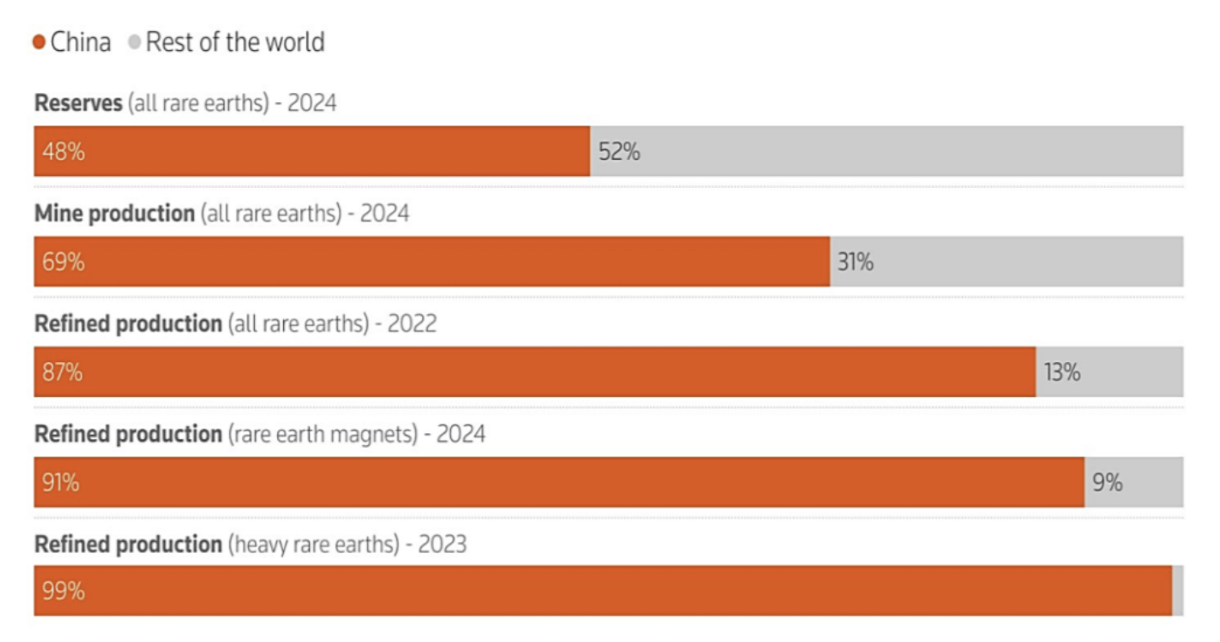

ADDRESSING CHINA'S REFINING DOMINANCE

China controls ~85% of global rare earth refining capacity, ~70% of mine production, and ~36% of reserves. Its grip is strongest in traditional solvent extraction (SX), a chemically intensive, multi-stage refining process. Most non-Chinese developers remain reliant on this infrastructure, creating a critical bottleneck for Western REE projects. Without scalable allied refining options, U.S. and other western REE assets often remain commercially stranded. The Company’s FJH technology upgrades complex feedstocks into chloride intermediates, which are directly compatible with Ucore’s RapidSX™ system, creating a scalable, onshore rare earth element oxide (REO) supply pathway.

This chloride-to-oxide pathway offers a compelling alternative to traditional SX flowsheets:

Decouples from Chinese refining infrastructure

Enables U.S.-based REE upgrading and separation

Deployable across diverse mineral and recycled feedstocks

Figure 5: Chinese dominance of the REE value chain – approximate percentage of control at each part

Figure 6: China accounts for >99% of global refining for heavy REEs

STRATEGIC TIMING

The collaboration comes amid accelerated U.S. government action to secure domestic supply chains:

In July 2025, the U.S. Department of War entered into a multibillion-dollar strategic partnership with MP Materials to accelerate U.S. rare earth magnet independence.

The package includes a US$400 million equity investment (positioning the DoW as MP’s largest shareholder), a 10-year NdPr floor price commitment of US$110/kg (double the spot price), and a 10-year magnet offtake agreement.

This marks a defining moment in the reshoring of REE magnet production and sends a strong signal of U.S. federal backing for vertically integrated rare earth supply chains.

Ucore recently secured a US$18.4 million contract from the U.S. Department of War to construct its commercial RapidSX™ module in Louisiana.

These developments signal a clear federal mandate to de-risk and scale vertically integrated, onshore rare earth processing, and Flash Metals USA’s FJH technology is now aligned with that mission.

The binding agreement is for a term of 12 months. Each party will enter into good-faith discussions to explore the potential of future commercial arrangements and collaboration. Each party shall retain all rights to their technology and binding non-disclosure agreements are in place between the parties. There are no commercial arrangements by way of fees or consideration associated with this collaboration agreement and each party is responsible for its own costs.

This collaboration complements Flash Metals USA’s Texas commercial-scale demonstration plant, which remains a core focus and is on track for dry commissioning by December 2025.

About Flash Metals USA

Flash Metals USA is a subsidiary of Metallium Ltd (ASX: MTM; OTCQX: MTMCF), an Australian-based company advancing sustainable mineral recovery and critical materials innovation. Flash Metals USA is pioneering advanced metal recovery solutions through its exclusive partnership with Rice University and the innovative Flash Joule Heating (FJH) process. The cutting-edge FJH process enables rapid, efficient extraction of materials such as lithium, gold, and gallium, reducing energy use and waste compared to traditional methods. By setting new industry standards for environmental responsibility and operational efficiency, Flash Metals USA is helping drive the transition to a more sustainable and circular economy.