News & Insights

Flash Joule Heating Breakthrough Enables Rare Earth Recovery from Magnet Waste

Peer-reviewed results validate Flash Metals USA’s patented process and confirm pathway to U.S.-based rare-earth refining capability.

October 15, 2025

Flash Metals USA, a subsidiary of Metallium Limited (“Metallium”) (ASX: MTM; OTCQX: MTMCF), announces that Rice University researchers have published peer-reviewed findings demonstrating a breakthrough method for recovering rare earth elements (REEs) from end-of-life magnets using Flash Joule Heating combined with chlorination (FJH-Cl₂).

KEY HIGHLIGHTS

Rice University researchers demonstrate rare earth element (REE) recovery from discarded NdFeB and SmCo magnets using Flash Joule Heating combined with chlorination (FJH-Cl₂).

Process delivered >90% purity and >90% yield in seconds, compared with many hours of acid leaching and solvent extraction in traditional hydrometallurgical processes.

87% lower energy use, 84% fewer greenhouse gas emissions, 54% lower operating costs, and complete elimination of acid and water consumption based on peer-reviewed life-cycle analysis. ▪ Generates commercially valuable by-products (Cobalt Chloride CoCl₂, Ferric Chloride FeCl₃) alongside REE recovery.

Creates a potential new high-value recycling pathway for magnet waste currently exported to China.

Flash Metals USA to trial the method in its Texas pilot prototype system, advancing commercialization of sustainable, U.S.-based supply chains for critical metals.

Flash Metals USA, a Metallium Company, Managing Director & CEO, Michael Walshe, commented: “Rice University’s breakthrough confirms what we see as the future of critical-metals processing: cleaner, faster, and vastly more efficient. The ability to recover rare earths from magnet waste at scale, with higher yields, lower costs, and zero acid or wastewater, represents a paradigm shift for global supply chains. Flash Metals USA is uniquely positioned, with exclusive rights to this technology, to take it from laboratory success into industrial reality. Our Texas pilot system is the crucial next step, giving investors clear visibility from world class science to commercial deployment and reinforcing Flash Metals USA’s leadership in establishing an independent U.S. rare earth refining and recycling capability.”

BREAKTHROUGH METHOD

The study, published in Proceedings of the National Academy of Sciences on 29 September 2025, was led by Professor James Tour and colleagues at Rice University (Xu et al. 2025).

Before processing, the Rice team demagnetized waste NdFeB and SmCo magnets by calcining at 800 °C for 30 minutes, heating them beyond their Curie temperatures to remove magnetic properties. The brittle, non-magnetic powders were then ground and sieved to <53 µm for consistent handling.

The method itself combines ultrafast Flash Joule Heating with a chlorine gas flow inside a quartz-tube reactor. When the magnet powder is rapidly heated on a conductive carbon substrate:

Transition metals such as Fe, Co, Cu, Ni, and Mn form volatile chlorides at lower boiling points and are removed.

Rare earth oxides convert to stable oxychlorides, remaining as concentrated residues.

The separation occurs in a single step lasting seconds, without solvents, acids, or wastewater.

By contrast:

Hydrometallurgy relies on acid leaching and multi-stage solvent extraction, producing large wastewater streams and requiring long processing times.

Pyrometallurgy involves smelting or roasting at very high temperatures with heavy energy consumption and secondary waste generation.

Life-cycle analysis confirmed that FJH-Cl₂ reduces energy consumption by 87%, greenhouse gas emissions by 84%, and operating costs by 54% compared with hydrometallurgy, while eliminating water and acid usage entirely (Xu et al. 2025).

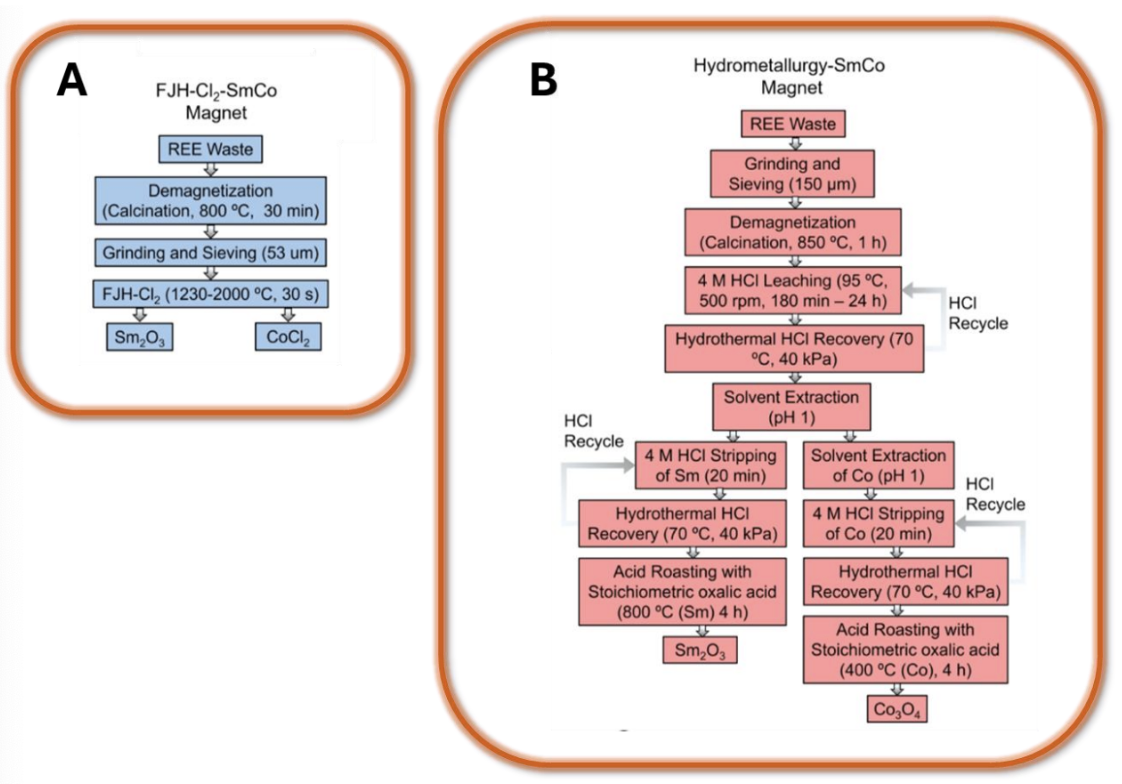

Figure 1: Comparison of samarium–cobalt (SmCo) magnet recycling methods (Xu et al., 2025

The above flow charts illustrate samarium and cobalt recovery from SmCo magnet waste using (left) Flash Joule Heating with chlorination (FJH-Cl₂) and (right) conventional hydrometallurgical processing. The FJH-Cl₂ route achieves separation in seconds at 1230–2000 °C with minimal chemical input, while hydrometallurgy requires multi-step acid leaching, solvent extraction, and hydrothermal stripping. Adapted from Xu et al. (2025), Proceedings of the National Academy of Sciences.

RARE EARTH MAGNET WASTE

Permanent magnets such as NdFeB (neodymium-iron-boron) and SmCo (samarium-cobalt) are essential components in electric vehicles, wind turbines, defense systems, and high-efficiency motors. Together they account for more than 90 percent of the world’s rare-earth magnet demand, yet almost all refining and recycling capacity is located in China (U.S. Department of Energy, 2023). The scale of this material loss underscores the importance of efficient and low-impact recovery technologies.

During manufacturing, around 10–20 percent of magnet material is lost as machining or polishing scrap, and a growing stream of end-of-life magnets from electric vehicles, wind turbines, and electronics is entering global waste flows. Most of this material is either exported to Asia for reprocessing or sent to landfill due to the high cost and environmental footprint of existing hydrometallurgical recycling routes (International Energy Agency, 2022).

This represents a major lost resource containing critical elements such as neodymium, dysprosium, samarium, and cobalt. Flash Metals USA’s use of Flash Joule Heating with chlorination enables rapid recovery of these elements without acids or wastewater, creating a scalable pathway for closed-loop magnet recycling within Western supply chains.

Figure 2: Periodic Table Highlighting Target Rare Earth Elements (Nd, Pr, Dy, Tb, Sm) and Cobalt (Co) in Permanent Magnet Applications

STRATEGIC CONTEXT – RARE EARTH INDEPENDENCE

China’s recent expansion of export restrictions, now covering additional rare-earth metals, refining equipment, and process technology, has intensified the urgency for non-Chinese supply chain solutions. According to recent reporting by the BBC (Hoskins and Bicker, 2025), Beijing’s tightening of rare-earth export rules now requires government approval for products containing even trace amounts of rare-earth material, extending to refining technology and magnet-manufacturing equipment. This underscores the immediate need for Western processing capacity independent of Chinese control.

Flash Metals USA’s binding collaboration with Ucore Rare Metals Inc. (TSXV: UCU; OTCQX: UURAF) delivers the first fully U.S.- based rare-earth refining pathway capable of treating both primary and recycled feedstocks. By integrating Flash Metals USA’s FJH upgrading process, which converts complex inputs into high-purity REE chlorides, with Ucore’s RapidSX™ separation technology, the partnership creates a versatile, modular, and China-free refining system that can process materials from mine concentrates, mixed rare-earth carbonates, magnet scrap, and industrial residues, a level of feedstock flexibility unmatched in current Western supply chains.

This technical breadth is strategically significant: most Western REE projects remain reliant on Chinese refining due to the complexity of feedstock variation. Flash Metals USA’s FJH process bypasses these limitations, producing clean chloride intermediates that plug directly into multiple downstream separation routes, whether for heavy or light REE compositions. This ability to handle heterogeneous materials from mine to magnet provides resilience against supply shocks and strengthens Flash Metals USA’s eligibility for U.S. federal critical minerals funding programs.

Flash Metals USA’s NEXT STEPS

Flash Metals USA, which holds exclusive rights to commercialize Flash Joule Heating for critical-metal recovery, will adapt these Rice University findings to its pilot-scale prototype system in Texas. This work forms part of the Company’s plan to build a national network of clean-tech metal recovery facilities anchored in the United States.

Figure 3: Texas Technology Campus will house the 1st FJH commercial plant & serve as a hub for ongoing R&D and future expansion.

About Flash Metals USA

Flash Metals USA is a subsidiary of Metallium Ltd (ASX: MTM; OTCQX: MTMCF), an Australian-based company advancing sustainable mineral recovery and critical materials innovation. Flash Metals USA is pioneering advanced metal recovery solutions through its exclusive partnership with Rice University and the innovative Flash Joule Heating (FJH) process. The cutting-edge FJH process enables rapid, efficient extraction of materials such as lithium, gold, and gallium, reducing energy use and waste compared to traditional methods. By setting new industry standards for environmental responsibility and operational efficiency, Flash Metals USA is helping drive the transition to a more sustainable and circular economy.